Mixing capacity:

45 – 90 l/min

Maximum grain size:

8 mm

Connection value:

400 V, 3 Ph, 50 Hz, 5.5 kW

Control voltage: 42 V

Drive motor:

5.5 kW, 292 rpm

Mixing tube:

Steel mixing tube

Pedestal:

Not included

Wheels:

Not included

Water connection:

Geka DN19 (3/4") – 2.5 bar working pressure

Operation and control:

Start/stop of mixing time via time relay or level indicator.

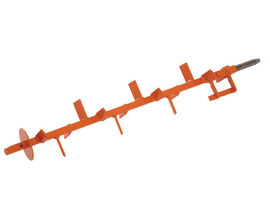

Agitator via mixer motor

Length/Width/Height:

2,325/390/395 mm

Total weight:

205 kg

Water flow meter:

150 – 1,500 l/h

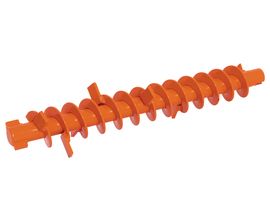

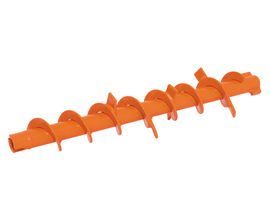

Dosing shaft:

60 l/min

Pressure booster pump:

Not included

Connection cable:

Not included

Water hose/air hose:

Not included

Silo/container handover:

Connecting flange Ø 250 mm