Mixing capacity:

30 l/min

Maximum grain size:

4 mm

Connection value:

230 V, 1 Ph, 50 Hz, 2.2 kW

Drive motor:

2.2 kW, 280 rpm

Mixing tube:

Rubber mixing tube

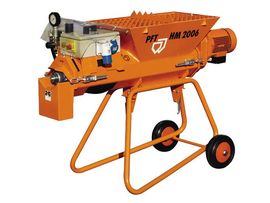

Pedestal:

Static

Wheels:

2 rollers

Water connection:

Geka DN12 (1/2") – 2.5 bar working pressure

Operation and control:

Start/Stop

Filling height:

1,000 mm

Hopper volume:

110 litres ~ 3.5 sacks (at 30 kg)

Outlet height:

600 mm

Length/Width/Height:

1,870/600/1,040 mm

Total weight:

100 kg

Water flow meter:

Not included

Dosing shaft:

30 l/min

Pressure booster pump:

Not included

Connection cable:

Not included

Water hose/air hose:

Not included

Silo/container handover:

Not possible