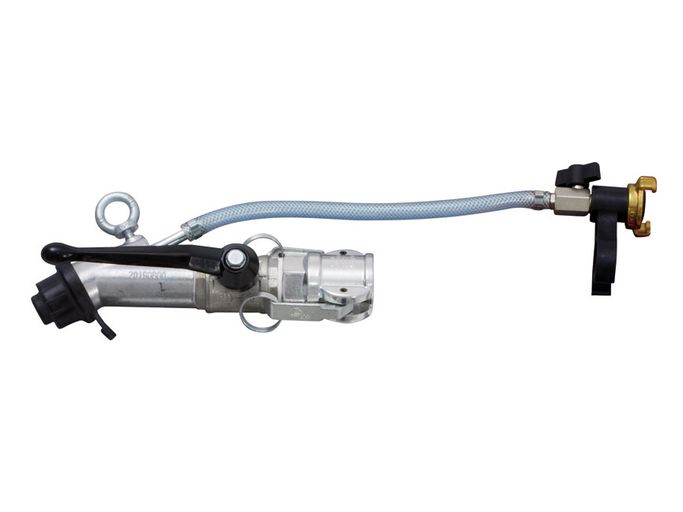

PFT spraying guns allow the grout mixed in the machine to be sprayed efficiently and uniformly. Opening and closing the air valve on the fine plaster spraying gun switches the machine on and off. For processing wall surfaces, we recommend a short spraying gun with a straight spray head. A spraying gun with a longer design and an offset head is useful for ceiling surfaces. To cope with longer hose lengths, the rotating joint on the spraying gun offers huge benefits. Helping you win the fight against twisted hoses. For retroactively swelling materials, such as insulating plasters, spraying guns with a ball valve or an automatic squeezer valve are used. For fine materials, and to guarantee a clean spray pattern (even in corners) the conical spraying caps are the right choice.

Spraying gun attachment:

1. Hose connection

2. Type of nozzle

3. Angle°

4. Length

5. Rotating coupling

6. Air connection

7. Ø Air nozzle