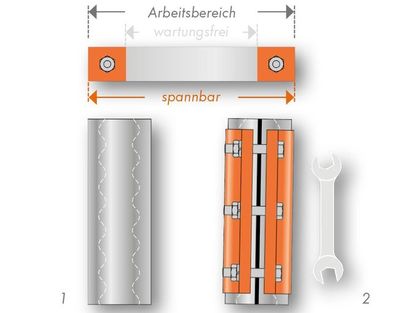

There are different types of stators. On the one hand the maintenance-free stators that are immediately ready for use after installation in the machine. Then there are tensible stators, which are tensioned depending on the material and grain size; these are in turn divided intotwo groups.

Stators with an integrated clamp and slotted stators that use an external clamp. If the conveying pressure decreases, the stators must be tightened. This substantially extends the service life. Robust design and high functionality are a matter of course for us.